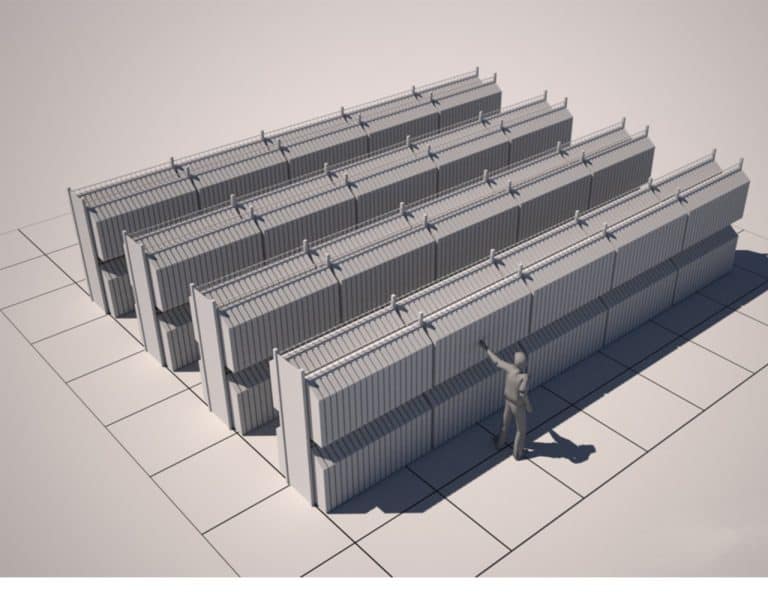

When transporting garments and other stock on site, overhead monorail systems are an efficient and cost-effective way of handling product to and from static locations.

Also known as a Garment on Hanger (GOH) system, the garments are typically suspended from roller trolleys that can move them over long distances.

The movement of the trolleys is manual and therefore controlled at all times, and a variety of functions and processes can be performed to precisely store, locate and move garments across your site.

Conveyor systems carry garments across a multi-level storage environment, including mezzanines, and can drastically reduce the labour required to move your stock between floors.