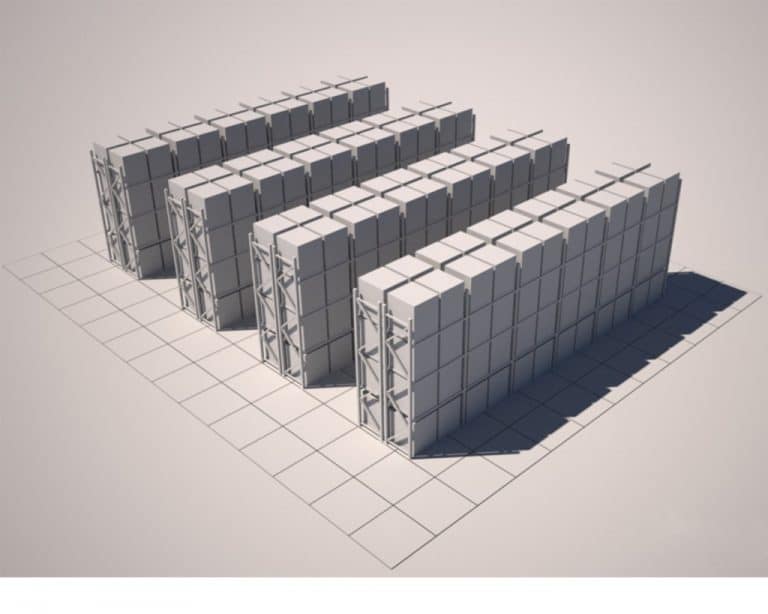

Specialist Very Narrow Aisle (VNA) forktrucks or cranes are used with this system, but they can lift higher, work faster within the aisle and operate with greater precision, accuracy and efficiency than standard trucks.

The VNA trucks have two standard means of guidance – either by floor-mounted rails or by wire embedded into the slab, which the truck picks up on.

If wire is used, it can improve access to the pallet at the floor location.

The risk of rack damage due to collision is reduced, as are maintenance costs – and pallets can only be reached by the VNA equipment, which helps to protect the security of your stock.

Variable heights and depths of shelving and height-adjustable supporting beams ensure you have maximum flexibility.